Veterinary drugs and pesticides are used routinely in animal production to manage diseases and control parasites, and crop protection chemicals are used in production of animal feeds. Chemical residues can occur in animal source foods and animal fiber via the purposeful administration of drugs or feeding of feedstuffs but can also occur through accidental drug exposure or unintentional exposure to contaminants in the feedstuff or in the environment. Regardless of how the exposure occurs, it is possible for foodstuffs of animal origin to be adulterated with residues of veterinary drugs and pesticides and for animal fibers to be contaminated with residues of ectoparasiticides. Veterinarians must consider the implications of these possibilities when providing for the health and welfare of animals. Animals and animal products destined for human consumption must not contain residues of drugs or pesticides that exceed legally permitted concentrations. Furthermore, pesticide residues in fiber have potential implications for public health, occupational health and safety, and environmental safety.

Chemical Residues in Foodstuffs of Animal Origin

Chemical residues can be found in animal tissues, milk, honey, or eggs after administration of veterinary drugs and medicated premixes, application of pesticides to animals, or consumption of feedstuffs previously treated with agricultural chemicals.

Veterinary Drugs, Medicated Feeds, or Application of Pesticides as the Source of Chemical Residues in Foodstuffs of Animal Origin

Managing risk from chemical residues in animal tissues and other products does not necessarily mean the products are residue-free, but rather that any finite residues remaining at the time of harvest are below an established safety threshold. Extensive regulatory and monitoring systems have been established to ensure that chemical residues in food do not constitute an unacceptable health risk. The premarket approval process undertaken by regulatory authorities for new veterinary drugs and medicated feeds evaluates the quality, safety, and efficacy of these products.

For veterinary medicines intended for administration to food-producing animals, an additional consideration is the safety of edible tissues and products (eg, milk, honey, or eggs) derived from treated animals. Regulatory authorities establish thresholds for residues that may safely remain and set withdrawal times to ensure that residues of the active constituent will not exceed that threshold when the label instructions for the product are followed. These limits are called maximum residue limits (MRLs) in countries of the Codex Alimentarius Commission and are called tolerances in the US.

Residue programs consist of two principal activities: monitoring and surveillance. Residue-monitoring programs randomly sample food commodities from animals. Samples are assayed for residues of specific veterinary drugs, pesticides, and environmental contaminants, and the residues are assessed for compliance with the applicable MRL or environmental standard. The number of samples taken for monitoring purposes are typically chosen to provide a 95% probability of detecting at least one violation assuming that 1% of the animal population contains residues above the MRL. Surveillance programs, by comparison, take samples from animals suspected of having violative residues on the basis of clinical signs or herd history. Food from animals identified with violative residues of veterinary drugs or pesticides does not enter the food chain. There are repercussions for the producer and, in the case of prescription drugs, for the veterinarian, when violative residues are found.

Residue monitoring is a trade requirement, either mandatory or as an expectation, of importing countries allowing market access to food products derived from animals. Compliance with the national standards of importing countries becomes more difficult when the health standards, regulatory policies, and MRL-setting approaches of the exporting country and importing country differ. The situation is further exacerbated when patterns of use differ across countries or when the minor status of a disease or pest in a country does not warrant product registration, in which case MRLs are unlikely to be established.

Regulatory authorities undertake premarket approval assessments of applications in support of new veterinary drugs and medicated feeds. These assessments consider scientific data submitted by the sponsor. In the case of veterinary medicines proposed for use in food-producing animals, the data must demonstrate the safety of any residues remaining in the edible tissues or products from treated animals. These data describe the compound’s toxicity, metabolism, pharmacokinetics, residue depletion, and dietary exposure. A number of key parameters are derived in the safety and residue evaluations:

The acceptable daily intake (ADI) is the amount of a veterinary drug, expressed on a body weight basis, that can be ingested daily over a lifetime without an appreciable risk to human health. The ADI is based on a review of animal studies on toxicological, pharmacological, or microbiological effects as appropriate. Conservative safety factors are built into the ADI.

The safe concentration is the maximal allowable concentration of total residues of toxicological concern in edible tissue. The safe concentration is calculated from the ADI and considers the body weight of an average person and the amount of meat, milk, honey, or eggs consumed daily by a high-consuming individual. Additional safety factors built into the safe concentration depend on the nature of the molecule under consideration.

An MRL, or tolerance, is the maximal concentration of residue resulting from the use of a veterinary drug (expressed in milligrams per kilogram or micrograms per kilogram on a fresh-weight basis) that is legally permitted as acceptable in or on an animal-origin food product. The MRL (or tolerance) is based on the type and amount of residue considered to have no toxicological hazard for human health as expressed by the ADI. Other relevant public health risks and aspects relating to food technology, good practice in the use of veterinary drugs, and analytic methodologies are also considered when establishing the MRL or tolerance.

The marker residue is the parent drug, its metabolites, or any combination of these, with a known relationship to the concentration of the total residue in the last tissue to deplete to the safe concentration. When the marker residue in the target tissue has depleted to the MRL, the total residue will have depleted to the safe concentration in all edible tissues.

The target tissue is the edible tissue with residues that deplete to a concentration below the MRL at a slower rate than that in all other edible tissues and is therefore suitable for monitoring for residues in each edible tissue from a treated animal. The target tissue is frequently liver or kidney for the purpose of domestic monitoring and is muscle or fat for monitoring meat or carcasses in international trade.

The withdrawal time is the period between the last administration of a drug and the detection of residues of that drug to concentrations below the MRL in food products from a treated animal. Compliance with the preslaughter withdrawal time aims to ensure that the total residues deplete to below the safe concentration and the marker residue depletes to below the MRL. Failure to observe the correct withdrawal time is the most common cause of violative residues of veterinary drugs in food.

Regulatory authorities base withdrawal times on residue depletion data that have been generated from healthy animals representative of those typically treated with the specific product. The drug formulation used in these trials is identical to the market formulation, which is administered in accordance with the label and at the maximal label rate. The withdrawal time is determined statistically, taking into account drug disposition variability among animals.

Unlike an MRL, which applies to a veterinary drug regardless of the dosage form, route of administration, or dosage regimen, the withdrawal time stated in the product labeling applies only to that particular formulation when administered by the recommended route and in accordance with the dosage regimen. Altering any of these factors modifies the pharmacokinetic behavior of the drug in the animal and invalidates the stated withdrawal time. In addition, a range of physiologic and pathological factors may modify the drug’s disposition in the animal and prolong drug elimination.

In the US, some veterinary or human drugs can be used in an extralabel manner in food-producing animals under the Animal Medicinal Drug Use Clarification Act (AMDUCA), provided that certain conditions are met (more information can be obtained on the FDA website). Veterinarians must be mindful, however, that in food-producing animals, the extralabel use of a small number of veterinary drugs is prohibited by the FDA. Extralabel use is use that is not included in the product labeling (ie, by a different route of administration, at a different frequency, or at a dosage rate other than that stated in the product labeling). In accordance with AMDUCA, anytime one of these factors is changed from what is on the FDA-approved label, the withdrawal time must be extended. The reason is that the withdrawal times are determined from the label instructions, and data are inadequate to demonstrate the safety of food products derived from the treated animal. An understanding of pharmacokinetic principles allows extended withdrawal times to be estimated both when veterinary drugs are used in an extralabel manner and in situations that may lead to changes in the kinetic behavior of a drug in an individual animal when treated in a manner inconsistent with the label.

Medicated feeds are not allowed to be used in an extralabel fashion in the US. In the US, the FDA amended the new animal drug regulations to implement the veterinary feed directive (VFD) section of the Animal Drug Availability Act, originally enacted in 1996. These changes were put in place as a measure to combat antimicrobial resistance by removing all antimicrobial use for production purposes. The final rule went into full effect in January 2017, and more information can be found on the FDA's website.

In the US and Canada, veterinarians have a resource to help determine an appropriate withdrawal interval after the administration of a drug in an extralabel manner or in the case of accidental exposure. The Food Animal Residue Avoidance Databank (FARAD) has a call-in service and a website where a veterinarian can submit a request for assistance.

In other instances, or in places where FARAD may not be available, an understanding of the pharmacokinetic principles involved as well as two relevant practical examples that demonstrate such occurrences, is essential.

The elimination half-life is the time for the concentration of a drug to be reduced by 50%. Over 10 half-lives, 99.9% of an administered dose is eliminated. The residues of drugs with longer terminal elimination half-lives take longer to deplete to below the MRL. The pharmacokinetic behavior of the drug determines whether the elimination half-life in tissues will exceed the elimination half-life in plasma. In food-producing animals, the terminal elimination half-life for the slow elimination phase, or gamma phase, of the residue concentration versus time profile determines the withdrawal time. Half-life (t1/2 [in hours]) is determined by the following relationship:

t½ = ln(2) × (Vd / Cl)

where the decimal value of the natural logarithm of 2 is approximately 0.693, Cl is clearance (in L/h), and Vd is volume of distribution (in L).

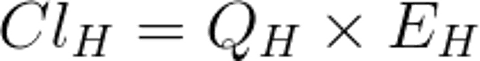

Clearance is the blood volume cleared of drug per unit time and refers to the irreversible elimination of a drug from the body. The principal organs of elimination are the liver and kidneys; organ clearance is related to blood flow and the efficiency of drug removal. For example, hepatic clearance (ClH) is determined as follows:

where QH = hepatic blood flow and EH = the hepatic extraction ratio. Factors that affect hepatic clearance include hepatic function, hepatic microsomal enzyme activity, and hepatic blood flow.

Volume of distribution (Vd) relates the amount of drug in the body to the concentration of drug in plasma. For a drug administered intravenously, Vd (in L) is determined as follows:

Vd = D/Cmax

where D is the dose (in mg) and Cmax is the maximal plasma concentration (in mg/L).

The Vd is a characteristic property of the drug rather than of the biological system. A drug confined to the vascular compartment has a minimal value of Vd equal to plasma volume. Factors influencing Vd include the size of the drug molecule, lipid solubility, drug pKa (acid dissociation constant), and tissue blood flow. Certain disease states effect changes in the Vd of a drug, particularly changes in drug binding.

As an example, if it is necessary to administer a drug to a healthy animal at twice the recommended rate, the elimination half-life of the drug remains unchanged. Assuming that the pharmacokinetic behavior of the drug demonstrates first-order kinetics, which is generally the case, doubling the administered dose will increase the depletion time by one half-life. Thus, the withdrawal time should be extended by one half-life to arrive at the same concentration as observed for the recommended rate. However, if a drug is administered to an unhealthy animal with impaired drug excretion in which clearance is reduced by 50%, reducing clearance by 50% will double the half-life. Accordingly, the withdrawal time should be doubled to arrive at the same concentration that occurs in an animal with a fully functional excretory system.

The predicted result should always be verified using a rapid-screening test. The detection of residues is likely to signal that the withdrawal time should be extended and the rapid-screening test repeated.

Feedstuffs Treated with Agricultural Chemicals as the Source of Chemical Residues in Foodstuffs of Animal Origin

The use of agricultural chemicals can result in residues in crops and pastures that are subsequently consumed by animals. During drought conditions, the feeding of potentially contaminated crop by-products (eg, stubbles and fodder) and processed fractions (including grape marc, citrus pulp, fruit pomace, and cannery wastes) is likely to become more prevalent. In all cases, chemical residues may end up in the edible tissues, milk, honey, or eggs derived from these animals.

For approved uses of crop protection chemicals that are likely to result in dietary exposure of food-producing animals, regulatory authorities establish animal commodity MRLs. The approach adopted for establishing these MRLs is fundamentally different from the one that applies to veterinary drugs. Animal transfer studies, which allow determination of the relationship between the amount of chemical in the animal diet and the concentration of residue found in edible tissues, milk, honey, and eggs, are pivotal in determining MRLs. The MRLs for animal tissues, milk, honey, and eggs are established at concentrations that cover the highest residues expected to be found from the estimated production animal dietary exposure.

Human dietary exposure assessments are also performed to verify that food complying with MRLs is safe for consumption. In animal production systems, compliance with animal commodity MRLs relies on adherence to a stipulated period to allow residues in the crop to deplete before it is fed to animals, a stipulated period to allow residues in the animal to deplete before slaughter, or a combination of both.

Veterinarians in the US and Canada may contact FARAD for assistance in determining a withdrawal interval after exposure of production animals to feedstuffs containing adulterant chemicals.

Chemical Residues in Animal Fibers

From an economic standpoint, the major animal fibers are wool and mohair. Many concepts with respect to pesticide residues in wool apply equally to mohair.

Flies, lice, keds, and mites adversely affect wool production and have animal welfare implications for the sheep industry. Ectoparasiticides have been the mainstay to manage infestations of these parasites in sheep flocks for many years. Two important manifestations of chemical application to sheep are the emergence of resistant strains of parasites and the contamination of wool with pesticide residues. These two factors are linked, insofar as the application of pesticides to resistant strains of flies or lice increases the likelihood of treatment failure and the need for repeated treatment later in the wool-growing season. Higher residues both in the wool on treated sheep and in harvested fleeces are possible consequences. Nonetheless, late-season applications are justified in some situations because of animal health and welfare or economic concerns.

Due to community health and safety expectations and changing environmental standards, wool producers are seeking ways to manage external parasites on sheep that rely less on chemicals. Integrated pest management (IPM) approaches may involve various husbandry options, such as shearing and crutching to combat fly-strike; genetic improvements, such as selecting against animals susceptible to fleece rot and fly-strike; biological and environmental controls, such as the use of fly traps; and the selective use of chemicals.

Pesticide residues in wool are influenced by many factors, including the chemical and formulation used, the method of application, the rate and timing of the chemical application, and the length of wool at the time of application. ( See also page Routes of Administration and Dosage Forms of Drugs.)

The product types and chemical groups commonly used in the management of flies and lice on sheep include off-shears backline or spray-on products containing insect growth regulators (IGRs), organophosphate pesticides (OPs), and synthetic pyrethroid pesticides; short-wool plunge or shower dips that use IGRs, magnesium fluorosilicate, OPs, and spinosad; long-wool backline or spray-on products containing IGRs; and long-wool jetting products containing IGRs, macrocyclic lactones, OPs, or spinosad.

Wool producers must ensure that pesticides are applied in accordance with the label directions. With some chemicals, application to sheep with > 6 weeks of wool growth results in unacceptably high residues remaining in wool to the next shearing. Repeated applications of pesticides may also result in higher wool residues at the next shearing, and backline products commonly leave higher residues at the site of application.

Although the use of sheep ectoparasiticides can result in appreciable chemical residues on treated wool, risk to public health is mitigated by the following steps:

First, scouring removes residual pesticide from processed wool destined for the manufacture of woolen garments.

Second, in the case of lanolin used in pharmaceuticals and cosmetics and as nipple emollients by nursing mothers, any residual pesticide associated with the wax component is removed during refining of the lanolin.

Additional assurance regarding the quality of low-pesticide grades of lanolin is provided by compliance with the applicable regulatory standards.

With respect to occupational health and safety, residual pesticide in wool wax poses a hazard to shearers and other wool handlers during wool harvesting. For instance, nervous disorders and dermal irritation have allegedly occurred in shearers after shearing sheep treated with certain OPs and synthetic pyrethroid pesticides, respectively. In addition, long-wool backline applications of synthetic pyrethroid pesticides can result in residue concentrations at the tips of backline staples high enough to cause dermal erythema in shearers and wool handlers. In Australia, such occupational health risks are managed by prescribing a sheep rehandling period in the product labeling. The sheep rehandling period is the time that must elapse between the application of the ectoparasiticide and safe handling of the treated animal. If sheep must be handled during the rehandling period, personal protective equipment should be used.

Chemical residues on treated wool may pose a risk to the environment when effluent is discharged during processing (eg, into rivers). This concern has led to the enactment of legislation to protect the environment. For some pesticides, environmental quality standards at concentrations that will not harm the most sensitive organisms in aquatic ecosystems have been established. In the EU, textile products are subject to eco-label requirements. In Australia, environmental risks posed by residues of ectoparasiticides on treated wool are mitigated by assigning a wool-harvesting interval (also referred to as a wool-withholding period). The wool-harvesting interval is the time that must elapse before treated sheep may be shorn, ensuring that harvested wool meets the prescribed environmental residue limits.

The depletion of pesticide residues in wool has been mathematically modeled to predict the likely consequences of treatments at different times during the wool-growing season and to determine how late a pesticide may be applied to sheep without resulting in excessive residues at shearing. Modeling is a useful tool to determine wool-harvesting intervals and to help wool producers choose a pesticide and method of application. Test kits to quantify pesticide residues in wool are also available.